Fabricating An Engine Stand For A 1998 Sportster

Since I couldn’t leave the engine hanging from the beam trolley forever, it was clear that it was time for an engine stand. Being impatient, and needing additional welding practice, the only reasonable approach was to build (as opposed to buy.) JIMS Engineering has a great looking engine stand, but required more money than I was willing to spend.

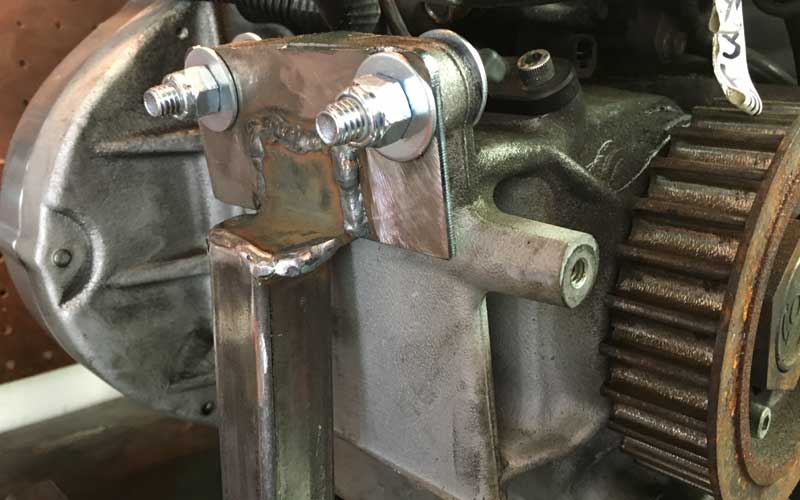

Measuring up the engine was easy since it was just hanging there. An early morning trip to the steel yeard provided more than enough 1″ square tubing and angle iron (both 11ga) for the project. Here are the parts ready for assembly, as well as some more photos of the result. You’ll see that I didn’t really leave the poor motor hanging for more than a night. Compassion.